Following fire safety tips for warehouses is very important as it can protect the lives of many employees working at your company.

Some equipment, such as forklifts and fire extinguishers, must be used in a company to provide safer and healthier employee protection.

Companies must teach employees basic skills, such as how to use safety gloves and where the fire extinguishers and eye washing stations should be placed.

So Here, we will discuss some warehouse fire safety tips that will help you prevent injuries and infections in your employees.

6 Steps Checklist For Warehouse Fire Safety

Quick Navigation

To ensure safety and protection for your employees, it is very important to follow some safety tips.

1. Provide warehouse safety training to the employees

Providing safety training to employees is the foremost step toward creating a safer and healthier working environment.

By creating such training events and workshops, company employees will learn about the safety steps they need to follow to prevent incidents.

2. By inserting warehouse safety signs

Installing warehouse safety signs can be the most efficient and cost-effective way to manage your warehouse properly.

The Warehouse safety signs should be placed in the main areas of the building, such as floors, racks, and safety equipment such as fire extinguishers.

Labeling emergency equipment such as fire extinguishers, eye-washing stations, and emergency exits. Labeling such safety signs reminds the employee to stay away from these danger zones as much as possible.

3. Safeguard the use of effective lightning

It is very important to ensure that your warehouse has a proper lighting system. Proper lighting is essential to a safer and healthier workplace environment.

A conventional lighting system prevents the employees from heavy equipment accidents and reduces the chances of damage to the property.

4. By installing the fire suppressing system

Installing a fire suppression system for your warehouse can be the most crucial safety protection tip for industries. With a fire suppression system, a sprinkler is installed with it.

Sprinklers are classified based on different categories and on what kind of products is being stored :

- Class I: The type of products used are non-combustible, and it is mainly used for pallets.

- Class II: The outputs used here are also incombustible and are suitable for wooden crates.

- Class III: These products comprise group C plastic material, wood, and paper.

- Class IV: This class of products is made from group A and B plastics.

5. Setting a proper ventilator

Setting up a proper ventilator is an essential part of warehouse safety, and it is necessary to examine the airflow of your warehouse. Make sure that the appropriate ventilator is used here.

6. PPE should be provided

Personal protective equipment such as surgical style or N95 masks, gloves, shoes, and head covers should be provided to the employees to reduce the chances of getting infected with communicable diseases. You can have a nice medical box store all these equipments for the security and safety of your warehouse.

Warehouse Fire Safety Checklist

Following are the check-points to ensure safety in the warehouse :

- Make sure that the fire extinguishers are placed properly.

- Ensure that the rack of your warehouse is not overloaded.

- Do double-checking your equipment twice or thrice a day

- Clean the warehouse floor properly

- Ensure that your bins are not overfilled

- Install security lighting in your warehouse

- Make sure that smoking zones are located far away from flammable materials.

- Ensure that your staff members know the location of the fire extinguishers.

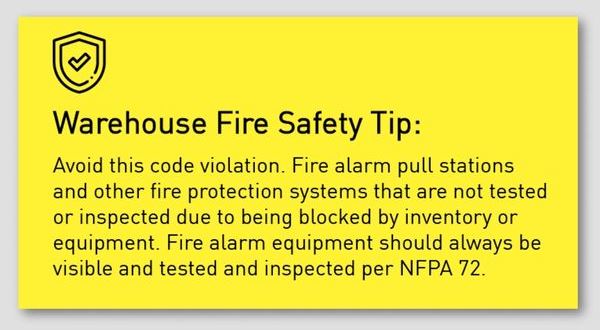

- Address fire alarm issues whenever needed.

- Check the connections of electrical wirings and power cords properly.

What is the first rule in fire safety?

- Fire safety is one of the significant components that should be taken seriously while designing a building.

- To have a safer and healthier working environment, it is essential to follow the foremost rule in fire safety.

- One of the foremost rules in fire safety is having sufficient space to escape emergencies.

- Open spaces have a wide role to play in emergencies, as it prevents employees from injuries and deadly accidents.

What does PPE stand for

PPE stands for Personal Protective Equipment which is designed for the employees to wear and it prevents them from chemical, electrical and mechanical risks.

These risks include fire accidents, injuries from sharp blades, heavy machines and accidents caused by working at heights. It does not matter what company you work for, be it in the laboratory or industry.

The workers need to wear PPEs while working, and it includes :

1. Gloves

Gloves prevent you from getting infected by contaminated substances while working in a factory or a laboratory.

2. Gloves and Head Covers

Shoes and headcovers act as protective shields to protect the shoes from getting dirty and protect you from communicable diseases.

3. Masks and respirators

Masks and respirators effectively protect you from industrial pollutants such as dust, smoke, mists and metal fumes. It protects from getting infected with respiratory infections.

4. Eye- protection goggles and face-shields

Eye- protection goggles provide effective safety as it blocks dust, mist, saliva droplets and chemical splash from entering your eye. While on the other hand, face shields protect your face, eyes, nose and mouth.

How will you ensure safety in the warehouse?

Following are the ways to ensure safety in the warehouse :

1. Plan a fire safety training

Planning fire safety training is very important to ensure safety in the warehouse. You can train the employees on how to use safety equipment through fire safety training. It also trains employees on how to escape whenever a deadly fire accident takes place.

2. By cleaning the warehouse floors

It is very important to have a properly clean warehouse to have a safer warehouse.

Warehouse floors should be managed properly to prevent slipping or falling, which can cause injuries.

3. By learning how to communicate with warehouse safety rules

As mentioned earlier in this article, we need to place the warehouse safety signs in the main areas of the building, such as on floors, racks, walls, and especially on safety equipment.

Mark the substances based on the quality of the present material, such as flammable, plastics, and harmful chemicals.

4. By discussing safety and warehouse incidents

Discussing fire accidents with your employees twice or thrice a month can play a major role in preventing deadly accidents in the future.

5. By double-checking the safety equipment

To ensure safety in the warehouse, ensure your safety equipment is working properly, such as fire extinguishers and sprinklers.

Double-checking the safety equipment twice or thrice a week can be an efficient and cost-effective way to have protective safety in the warehouse.

Final talk

Most of the time, fire accidents can be threatening. They not only cause damage to the property but can also cause deadly fire accidents and injuries. There are different protection guides and checklists for restaurants, offices, and warehouses.

It is important to follow proper fire safety management to prevent the chances of deadly fire accidents training the employees about the importance of fire management can play a major role in creating a safer environment.

Leave a Reply