Sizing and selection of a fire pump majorly depend on the type of project and fire you want to extinguish. There are several factors that you need to notice during the selection. One such factor is temperature.

If your project has a lot of hot areas, it may be better to use a low-temperature fire pump instead. This will resist the water from boiling and causing damage to the surrounding.

Another factor that affects the type of fire pump is when you should use, how much water pressure is needed for your project. You need more pressure to keep your sprinklers operating at their capacity.

You need to have a better understanding during the selection of a fire pump, hence read the article till the end!

How To Do Fire Pump Sizing And Selection?

Quick Navigation

Fire pump sizing and selection are critical because of different pricing and uses of the fire sprinkler system design. This article will guide you through the basics of fire pump calculation and cover some tips and tricks to consider during your design.

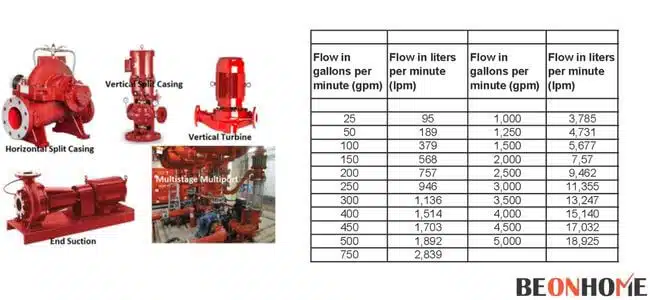

The first step to understanding fire pump sizing is knowing the types of pumps available.

The most common types are:

- Electric Centrifugal – This type consists of a single-stage impeller on a shaft. It is the most commonly installed type of fire pump.

- Diesel Engine Centrifugal – A diesel engine powers this centrifugal fire pump. Which may be either base-mounted or skid mounted at the point of use.

- Vertical Turbine – This type of pump consists of a multi-stage impeller mounted on a vertical shaft. An electric motor or diesel engine drives it.

There are three steps in fire pump sizing:

- The first step is figuring out what type of fuel system your building uses. What will the flow rate be required to put out a fire using that system? The NFPA has developed a chart for this purpose, which you can find here.

- The second step is finding the appropriate pipe size. It depends on the size of the sprinkler heads. This information can be found on the nozzle/sprinkler head itself. Which should display its K factor or flow coefficient. Using this information, you can calculate the PSI. It will help you determine the appropriate pipe size.

- The third step is determining the friction loss for your pipes. To do this, you’ll need to know how long the pipes are in total and how many elbows there are in your piping system. The NFPA has developed a tool to help with this process, which can be found here: [link].

Once all these steps have been completed. You will have enough information to determine the size required.

How Do I Know What Size Fire Pump I Need?

Whether installing a fire pump in a new building or replacing an existing one. It’s important to know what size pump you’ll need. Three factors will affect how large a pump you need:

- Your pressure requirements;

- The total flow rate of your system

The pressure loss through the piping itself.

- First, determine your pressure requirements. This is a matter of looking at your local fire codes. Your local authorities will specify the minimum discharge pressure required for your building.

- Then, consider any additional friction loss your system might go through. You can calculate this by looking at the number of elbows or other fittings in the line. Or whether there is any vertical rise in the pipes themselves.

- Next, figure out what flow rate you’ll need to achieve. Some pumps can only handle up to a certain flow rate. If your flow exceeds that amount, you’ll have to look for a different type of pump. Then, take into account losses from friction from the piping itself. (which we covered earlier).

- Finally, consider what kind of power source you’ll need for your fire pump. Pumps come in both diesel and electric varieties. You’ll have to choose which kind will be best for you based on factors like cost and maintenance.

Sizing The Fire Pump

It’s pretty easy to understand the need for a fire pump, but it can be hard to know what size of fire pump you need. This is because a fire pump’s flow rate and pressure requirements will depend on various factors.

The first thing you must do is calculate the area of the sprinkler system hydraulically. You must determine what type of sprinkler heads are used to get this number. The flow rate and density of each one. You can then use these numbers to calculate the total area of your sprinkler system.

Now that you have your area, you can use simple math calculations to determine the required flow rate.

Flow Rate (GPM) = Area * Density * 0.0545

Pressure (PSI) = Area * Density * 2.5

These figures will help you decide what size fire pump you need and its flow rate and pressure.

How Do You Size A Fire Jokey Pump?

Sizing a fire pump is simple if you know your sprinkler system’s required flow and pressure. You can use this calculator to determine your needed flow and pressure. But it’s important to remember that this flow rate may change from project to project.

There are four main considerations to make when sizing a fire jockey pump. Continuous flow, discharge pressure, tank size and location, and static water pressure.

- The first consideration is the water flow rate. Different buildings require different amounts of water flow. Which can be determined by local fire codes. A building with a higher flow rate will generally require a larger jockey pump than one with a lower flow rate.

- The second consideration is the discharge pressure. The higher the discharge pressure, the more power you will need from your fire pump. It’s important to know that this is not the same as static water pressure. The pump will generate far more than static water pressure during operation.

- The third consideration is tank size and location. A smaller tank in a more remote location will likely require a larger fire pump than a larger tank nearby. Because of the increased friction and energy loss over longer distances.

- The fourth consideration is static water pressure. The lower your static water pressure, the higher your jockey pump output will need to be. But it’s important not to try to boost your static water pressure above its intended levels. Because of potential damage to pipes and other equipment.

How To Inspect The Size Of a Fire Pump?

Here are some tips on inspecting a fire pump’s size.

- Look at the label and see if there’s anything written on it. If you don’t know what a fire pump is, ask someone who does.

- Check the size of the nozzle. Fire pumps have nozzles that release water or other liquids to put out fires. You should be able to tell what size nozzle is needed by looking at the labels of your fire pump.

- If your pump has an adjustable nozzle, use it until you find out how many gallons it can hold. The number should be on the label somewhere.

The size of the fire pump is one of the most important factors you must consider. When selecting a fire pump for your building.

If you select an undersized pump, it can result in damage to your property and loss of life. If you select an oversized pump, you would be wasting money on a more powerful pump than necessary.

To inspect the size of a fire pump, you need to know two things. How much water will you need, and how much pressure is needed to get water to where it needs to go within your building? You can calculate these numbers or find them online easily.

Once you know these values, you can use this formula: flow (GPM) / pressure (PSI) = horsepower (HP). The numerical answer for horsepower is the number that should go on your fire pump motor nameplate.

What Is The Capacity Of The Fire Pump?

To properly maintain your fire pump, it is essential for you to know its capacity. What is the capacity of the fire pump? The capacity is determined by the amount of water delivered at a given pressure.

It is generally expressed in gallons per minute (GPM) or liters per minute (LPM). While this information can vary depending on what type of system you have. Here are some general guidelines:

- The fire protection system must have enough power to handle any water demand. This includes both hot and cold weather conditions. As well as potential changes in the building’s use over time. (for example, if it was converted from an office space into an apartment complex).

- The supply line must be sized based on how much water needs to flow through it per minute.

- This figure should be calculated by multiplying all possible water uses at once. (e.g., sprinkler heads spraying simultaneously. Then add two gallons per minute for every 10 mins).

Final Talk

In conclusion, fire pump sizing and selection are critical to a fire sprinkler system. Without your fire pump’s proper design and size, you can have a weak or underperforming system. The best way to ensure proper sizing is to consult with a professional. Or a qualified fire protection company.

Leave a Reply