Technology is discovering various instruments, gadgets, and devices based on comfort. Explosion through a gas leak and ill effects on human health has become a subject of discussion.

The employees die from their exposure to toxic gasses. In earlier days, workers used to carry a canary bird as an instrument of gas detection.

But, now, we can detect the presence of harmful gasses in the area through gas detectors. These devices have not only made operations easier but also have decreased accidents. Here’s everything you should know about the gas detector.

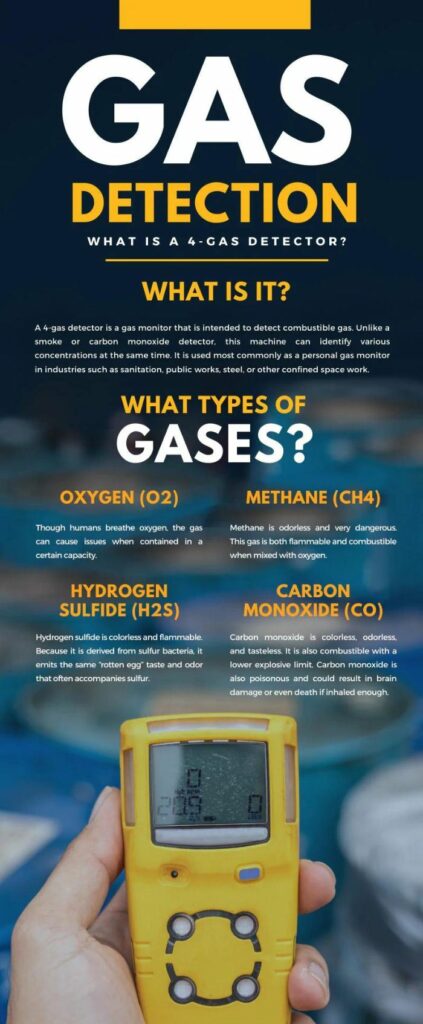

What Is A Gas Detector?

Quick Navigation

A Gas detector is a tool used to recognize many forms of gas in the air. These gas detectors can detect the presence of gas in the atmosphere within a couple of seconds.

Gas sensors can be used both by families and industries. It has sophisticated instruments that are treated as the best inventions by scientists.

They can check for toxic gasses present in an area. It can detect different types of toxic gasses in humans and creatures. The human nose can hardly detect the odor of a gas present in a room, but a gas detector can.

Gas detectors can detect gasses such as methane, carbon dioxide, carbon monoxide, hydrogen, butane, and propane. They can detect flammable, explosive, old toxic gasses and oxygen depletion.

Why Are Gas Detectors Important?

Gas detectors are essential because they act as an early warning signal, saving your life. Before your nose senses a toxic gas in the air, these detectors will start providing you with indications.

The alarms are unavoidable; no one can ignore them. As discussed earlier, these gas detector helps to detect destructive gasses in the air. It also helps in identifying deficiency of oxygen. It also prevents destruction and property damage, which may occur after the gastric explosion.

Exposure to these gasses not only disrupts the human body but can also lead them to death. Hence, it can conclude that these devices prevent mishaps and last life saviors.

Advantages of Gas Detectors

Gas detectors are essential irrespective of the fact where you work. Gas detectors can be used by families and also by industrialists.

This beneficiary device has many advantages, and some of them are discussed below:

1. They act as a warning signal

Within a short period, these sensors warn you about the level of toxic gas present in the air. Once they detect a higher than the natural gas concentration in the atmosphere, they produce required beeps. The people use these indications to leave that area immediately. Hence, they act as a warning signal.

2. Availability of different variations

These gas detectors are developed according to the nature of a particular area. For instance, mineworkers use multi-gas sensors, where this device can detect different gasses at once.

Families can use gas sensors that sense cooking gas like liquified petroleum gas (LPG) etc. Consumers choose these sensors according to the demand of their territory.

3. Battery Operated

These devices are generally battery-operated, which means they run on batteries. This feature makes these sensors extra worth a fortune.

You don’t need to worry if your electricity supply is cut-off. These detectors can work without electricity. Hence, no chance of disruption.

4. Durability

Gas detectors are durable. Their working life is five years. If proper maintenance is performed, it can also work for more than five years. Its durability may vary depending upon the quality and maintenance.

Working Of Gas Detectors

Gas Detectors work in a super-easy way. As soon as they observe a leak, they start monitoring the level of gas and its types present in the air.

After detection, the alarm begins producing unavoidable loud beeps. These devices work on threshold systems. There is a chance of a certain amount of gas in the atmosphere.

The detection can only occur when the toxic gas concentration exceeds the oxygen level. If you receive signals, oxygen level decreases. Moreover, make sure you do have a good gas flow meter at your place to control a shut-off gas supply if the detector detects it. You also need to have a good emergency shut-off tool for leaking gas.

How To Install?

The most critical part of these devices is their installation. They will not work if their installation has some issues.

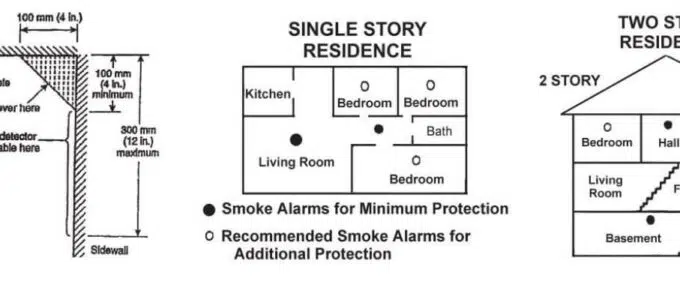

1. Positioning

It is essential to keep in mind the positioning of the gas detectors. If the density of a particular gas is heavier than air, then these detectors should be placed near the floor;

Whereas, if the gas is lighter than the air, then should install ceiling detectors; The reason behind this is straightforward. Gas detectors need to come in contact with the gas; only then would they be able to work. So, the installation of gas detectors depends on the density of the gas.

2. Investigation

It would help if you also investigated the airflow conditions and potential gas pocket areas because gas flow is consistent.

Remember not to place or install the detector where there is constant vibration; it may harm the detector. Use a plane and stable space such as a wall to install the sensor.

Their installation is done in confined spaces with a higher risk of toxic exposure or fire.

For example – Power plants, any production factories, homes, restaurants, etc.

Below we have discussed the steps to install an average gas leakage detector:-

- Open the cover by removing the screws. A normal GLD consists of six to eight screws.

- You will find a green board in which vertical plugin connectors streamline the wiring.

- Now, wire the alarm siren to relay 2 and the warning siren to relay 1.

- If needed, connect the serial line from the monitoring system or main control machine.

- Further, connect the GLD to the power supply and screw the cover back.

- Connect the GLD to the monitoring system via the serial cable.

- Open or install the Rileva app or any other app as far as the type of GLD is concerned and enable Bluetooth on your phone.

- Activate Bluetooth on the GLD using the magnetic pen; the switch must be near somewhere on the left.

- Now you need to select the GLD as soon as your phone finds it.

- Complete the configuration and insert the appropriate password.

- You can name the device for fast future recognition.

- You can see an alarm page where you need to click on the low alarm point and set the low threshold gas concentration level.

- Remember, that address must be different from any other serial device on the same network.

Since there are wide varieties of gas detectors, the installation process may vary. You can take help from the instruction manual for more information and clarity.

Types Of Gas Detectors

There are thousands of harmful gasses present in our environment. Exposure to it causes ill effects on our health. Gas detectors can sense wide varieties of these gasses, consisting of different designs and models. There are many types of gas detectors; the following are some of them:

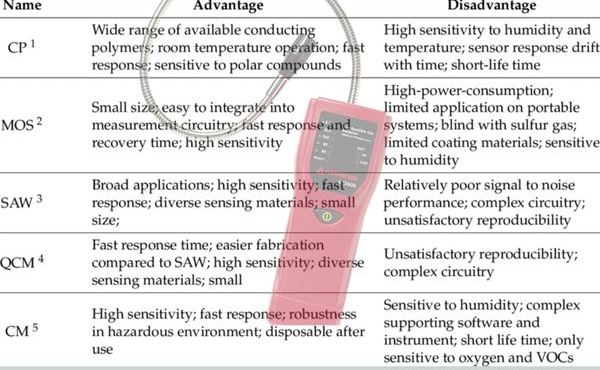

1. Electrochemical gas detector –

These sensitive gas detectors detect harmful gasses such as chlorine, carbon monoxide, and nitrogen oxides. The working is done by diffusing an electrode to a porous membrane by enabling gasses.

It contains a particular porous barrier that detects a specific gas concentration range. These barriers can also be customized or changed by the manufacturers. An electrode comes in contact with the target gas; these sensitive sensors emit an electrical signal.

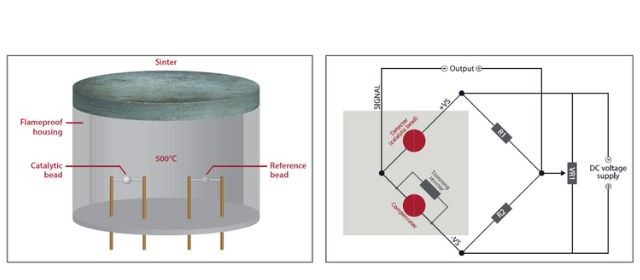

2. Catalytic bead (pellistor) –

These sensors have a bit different operations. A catalytic bead consists of a surface known as a catalyst, where combustion occurs as soon as a combustible gas or mixture of air passes over the hot surface.

As a result, the temperature is increased by the heat of the catalytic sensors consisting of platinum wire coils termed sensing elements. The resistance of a platinum coil is measured by using the coil as a temperature thermometer in a standard electrical bridge circuit.

These are used to measure combustible gasses that cause explosions. These sensors are reasonable, but they require the lowest percentage of oxygen in the atmosphere for testing.

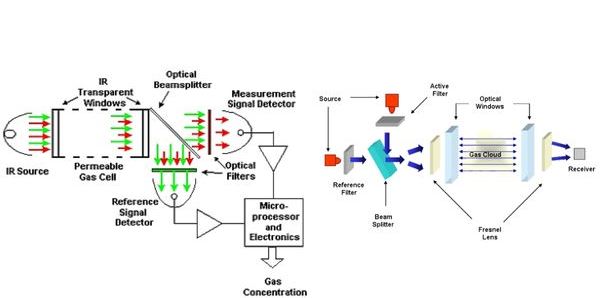

3. Infrared point sensors –

these sensors work with the help of radiation that passes through a known volume of gas. The properties of the gas present in the air are defined at specific wavelengths as the energy from the sensor beam is absorbed.

One advantage of these detectors is that they may choose their placement far from the area because they do not need to be in contact with the gas to detect it. These sensors help in detecting hydrocarbons, water vapor, and carbon dioxide.

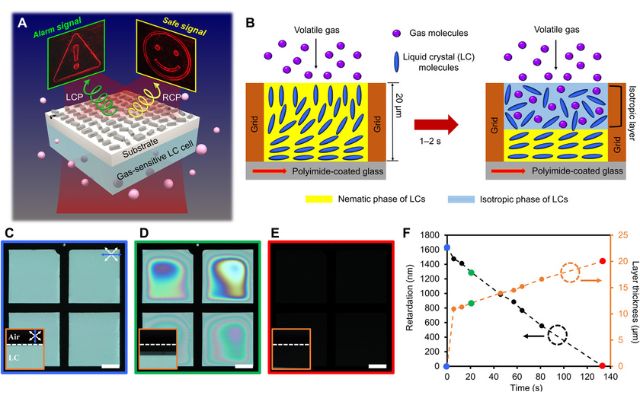

4. Holographic –

these detectors detect changes in a film matrix made of polymer containing a hologram by the reflection from a light detector. Whenever this hologram comes in contact with a gas molecule, it starts reflecting light at a specific wavelength. As the composition changes, a colorful reflection indicates a molecule’s presence.

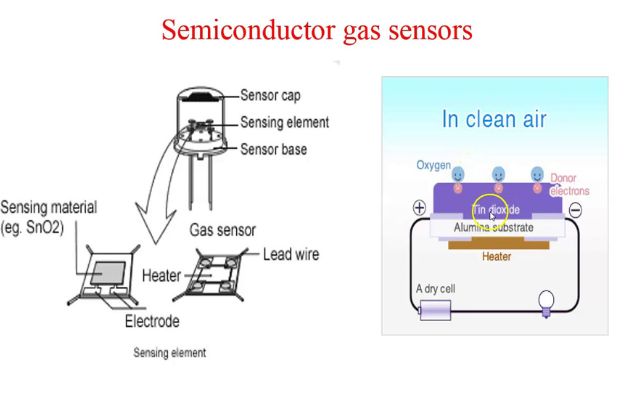

5. Semiconductors –

These are also known as metal oxide semiconductors. They contain a gas-sensitive film that is made of tin or tungsten oxide. A chemical reaction occurs when the gas comes in contact with the film.

They perform well in low humid regions. They detect toxic gasses and can also detect combustibles like oxygen, alcohol vapor, hydrogen, and carbon monoxide.

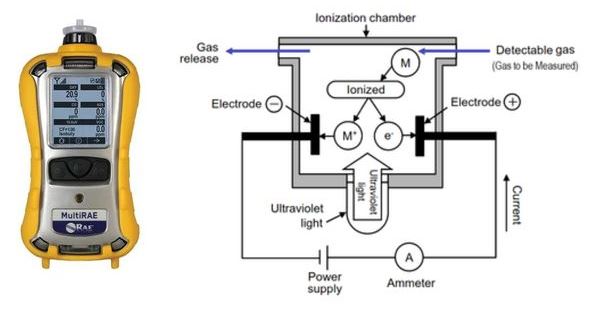

6. Photoionization

Photoionization detectors, also known as PIDs, work by ionizing the chemicals in the sampled gas using a UV lamp with high-photon energy. Suppose the ionization energy of the compound is below that of the lamp photon. In that case, the ejection of an electron occurs where the resulting current is proportional to the concentration of the compound.

10.0 eV, 10.6 eV, and 11.7 eV are some of the typical lamp photon energies; here, the most standard power is 10.6, which usually lasts for years compared to 11.7 eV because it only lasts for a few months. PDIs become more advantageous because of their excellent sensitivity and ease of use.

Some widely used PDIs are Fixed, hand-held, and miniature clothing-clipped PIDs. These are mostly used for hazmat, environmental monitoring, and industrial hygiene. But they have a limitation, too; they do not provide compound-specific measurements.

7. Ultrasonic

Ultrasonic gas leak detectors can not be fully categorized as gas detectors because they detect the acoustic emission created through a small leak when a pressured gas expands in a low-pressure area. A sensor termed the acoustic sensor is used to recognize changes in the background noise of their environment.

Usually, high-pressure gas leaks generate sound in the ultrasonic range of 25 kHz to 10 MHz. 20 Hz to 20 kHz is the audible range in which these sensors can identify the background noise.

If the background noise is not normal, the ultrasonic gas leak detector starts to produce an alarm. In simple terms, ultrasonic detectors do not detect gas but detect the leak rate of an escaping gas through the ultrasonic sound level.

These devices are best for outdoor environments where weather conditioning may dispel the leaked gas before it can contact the actual gas detectors. Gas compressor and metering stations and offshore and onshore oil/gas platforms are some areas where ultrasonic gas detectors are used. So never forget to have a good ultrasonic gas leak detector at your home or workplace.

8. Infrared Imaging

These image sensors consist of active and passive systems. In active sensing, laser scanning is done by imaging sensors across the field of view of a scene. After that, it looks for a backscattered light at the absorption line wavelength of a specific target gas.

On the other hand, passive imaging sensors look for specific spectral signatures indicating the presence of gas in an image whenever there is a spectral change at each pixel. The images are beneficial in identifying the target gas.

How To Calibrate?

Calibration means-testing. This topic will discuss how to test the gas detectors. Before jumping into the calibration test of gas detectors, ensure you have all the necessary tools and an appropriate environment. Choose a properly ventilated space when performing a calibration test. Below are the steps you need to follow:

- Pick the calibration gas cylinder and connect the regulator;

- Screw the bottom part of the regulator on the top of the calibration gas cylinder. On that top connection, connect the sampling hose;

- Now, look for the airtight clip and attach the same to the gas detector. Ensure that you choose the right clip for the suitable gas detector because different classes of gas detectors may have various clips;

- Connecting the sampling hose to the clip will make sure that the entry of the gas will point in the direction of flow;

- By opening the regulator, turn on the gas cylinder. You will hear a beep. An internal alarm will start ringing after a few seconds because the gasses will not flow through the clip.

- Lastly, turn off the ringing alarm, and detach the regulator and the sampling hose. Don’t forget to ventilate the gasses.

Things To Remember While Purchasing

- While purchasing, you need to be clear that all detectors are not the same. Many sensors are multi-functional, and others are not.

- Some of them can only identify smoke. So be aware of the gas type and the detector which will suit your demand.

- Whether the place has an electromagnetic interface, whether it is corrosive or the location is humid, or it is scorched. A detector can only work if the environment is friendly to it.

- Check the certification, such as CE certification, fire protection certification, 3c certification, explosion-proof certification, UL certification, etc. It provides the product an authorization over the quality.

- These sophisticated devices come at an affordable price range from $100-$200. Depending upon the quality and quantity, prices may differ.

FAQ

1. What gasses do gas detectors detect?

Gas detectors can detect carbon monoxide, sulfur dioxide, hydrogen sulfide, and ammonia. They can detect all combustible and flammable gasses which are not familiar to the environment and are hazardous. You can have a high quality hydrogen sulphide gas detector for your safety.

2. What is a natural gas detector?

A natural gas detector can be battery-powered, or you need to plug it into the wall. Natural gas detectors monitor the particles in the air and help in alerting the homeowner or the people when there are any indications of gas leaks.

3. What is a portable gas detector?

As the name suggests, portable gas detectors are personal protective equipment that helps keep oneself or personnel safe from atmospheric hazards caused due to gasses.

Final Talk

Where there is development, there is destruction too. But we can prevent it and keep our people safe. We come across many news articles informing us about explosions through gas leaks. Life is uncertain and risky; we cannot see future mishaps. It becomes our priority to prevent them. It not only affects society but also causes the deaths of innocent people. Gas detectors need to be used by every industrialist, factory worker, and miner. It is said that prevention is better than cure. Hence it becomes mandatory for everyone to take these safety devices into notice.

Leave a Reply